What is a Lapel Pin: The Ultimate Guide to Lapel Pins in 2025

Table of Contents:

- Introduction to Lapel Pins

- The History and Evolution of Lapel Pins

- Different Types of Lapel Pins

- Materials Used in Lapel Pin Manufacturing

- The Lapel Pin Manufacturing Process

- How to Wear a Lapel Pin Correctly

- Popular Uses and Occasions for Lapel Pins

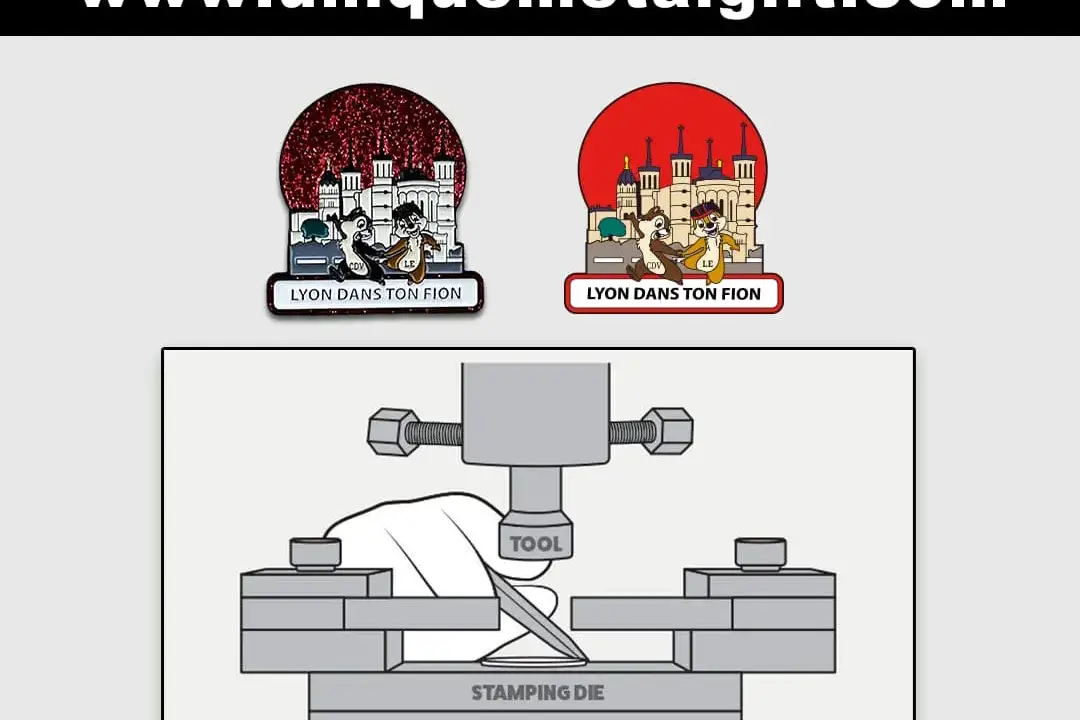

- Custom Lapel Pin Design: Creating Your Own Pin

- Lapel Pin Care and Maintenance

- Lapel Pin Market Trends in 2025

- FAQ About Lapel Pins

Introduction to Lapel Pins

Lapel pins, those small yet significant accessories that adorn jackets, bags, and various clothing items, have gained popularity in recent years. But what exactly is a lapel pin? A lapel pin is a small, decorative pin typically worn on the lapel of a jacket or coat, although its versatility extends far beyond this traditional placement. These miniature works of art serve as symbols of achievement, affiliation, personal expression, or simply as fashionable accessories that add a touch of personality to any outfit.

Often confused with their close relative, the enamel pin, lapel pins encompass a broader category. While all enamel pins can be considered lapel pins, not all lapel pins are enamel pins. The distinction lies primarily in the manufacturing process and materials used. Enamel pins specifically refer to those made with enamel coloring, while lapel pins can be crafted from various materials and through different techniques.

The basic anatomy of a lapel pin includes the face or front design, the post or pin that secures it to fabric, and the backing or clutch that holds it in place. This simple structure belies the incredible diversity and craftsmanship that goes into creating these small accessories. From simple monochromatic designs to intricate, colorful masterpieces, lapel pins offer endless possibilities for personal expression and professional representation.

In today’s fashion landscape, lapel pins have transcended their traditional role as formal accessories or organizational emblems. They’ve become collectible items, conversation starters, and powerful symbols of personal identity. Whether you’re a seasoned collector, a fashion enthusiast, or simply curious about these small yet impactful accessories, this comprehensive guide will take you through everything you need to know about lapel pins in 2025.

The History and Evolution of Lapel Pins

The history of lapel pins stretches back thousands of years, with their origins deeply intertwined with the ancient art of jewelry making and symbolic adornment. While the modern lapel pin as we know it today may be relatively recent, the concept of wearing small decorative items as symbols of status, affiliation, or achievement has ancient roots.

Ancient Origins

The techniques used to create lapel pins, particularly the cloisonné method, can be traced back to ancient Egypt around 4,000 years ago. Archaeological evidence shows that ancient Egyptians used enamel to decorate pottery and jewelry, with examples found in tombs alongside mummies. This sophisticated technique involved creating small compartments (cloisons) that were then filled with colored enamel or glass paste and fired at high temperatures.

From Egypt, these decorative techniques spread to other civilizations, including China and Japan, where they were refined and adapted to local artistic traditions. The Byzantine Empire further developed these methods, creating intricate enamel works that would influence European decorative arts for centuries to come.

Military and Organizational Insignia

The direct predecessors to modern lapel pins emerged in the form of military insignia and organizational badges. In the United States, the Civil War (1861-1865) marked a significant moment in lapel pin history, as soldiers from both the Union and Confederate armies wore pins to distinguish themselves. These early military pins served a practical purpose—identification on the battlefield—but also fostered a sense of unity and belonging among troops.

By World War I, pins had evolved to signify different honors and awards in the military, a tradition that continues today. Military service pins, rank insignia, and achievement medals all share DNA with the modern lapel pin, emphasizing their role as symbols of accomplishment and affiliation.

Political and Social Movements

Throughout the 19th and 20th centuries, lapel pins became powerful tools for political expression. Campaign buttons and pins allowed citizens to publicly display their support for candidates or causes. During times of national crisis, such as World War II, patriotic pins became popular ways to show solidarity and support for the war effort.

In the Soviet Union and other communist countries, pins featuring political figures like Lenin and Mao Zedong were widely distributed and worn as symbols of party loyalty. Interestingly, in some contexts, these same pins were later worn ironically or as forms of subtle protest, demonstrating the complex social meanings these small objects could carry.

The Modern Pin Revival

After a period of relative decline in popularity during the late 20th century, lapel pins experienced what some have called a “pin revival” beginning around 2014. This resurgence was largely driven by independent artists and designers who began creating pins with countless different designs—from traditional emblems to pop culture references, emojis, foods, plants, and abstract art.

Social media platforms like Instagram facilitated this revival, allowing collectors to showcase their collections and artists to market their creations directly to enthusiasts. The trend grew so significantly that major cities began hosting pin shows and conventions, such as New York City’s first Pin and Patch Show, which attracted thousands of attendees.

Today, lapel pins occupy a unique cultural space, simultaneously serving as professional accessories, fashion statements, collectible art pieces, and symbols of personal identity. Their evolution from ancient decorative techniques to modern mass-produced items and finally to limited-edition artistic creations reflects broader trends in how we express identity and affiliation through personal adornment.

Different Types of Lapel Pins

The world of lapel pins is remarkably diverse, with various manufacturing techniques resulting in distinct styles, each with its own aesthetic qualities and practical considerations. Understanding these different types can help you choose the perfect pin for your specific needs, whether you’re collecting, commemorating an event, or expressing your personal style.

Soft enamel pins are among the most popular and widely produced types of lapel pins today. Their defining characteristic is the textured feel created by raised metal edges that separate areas of color. This creates a distinctive tactile experience when you run your finger across the surface of the pin.

The manufacturing process begins with a metal mold that forms the base shape and design of the pin. Metal edges are added to create recessed areas, which are then partially filled with colored enamel. Because these recessed areas are only filled about halfway, the metal borders remain raised above the enamel surface, creating that characteristic texture.

After the enamel is applied, the pin is baked to set the colors. Soft enamel pins offer vibrant color options and can accommodate intricate designs at a relatively affordable price point, making them popular choices for custom pins, promotional items, and collectibles.

Hard enamel pins, also known as cloisonné pins, represent the premium end of the lapel pin spectrum. Unlike their soft enamel counterparts, hard enamel pins feature a smooth, polished surface where the enamel is level with the metal borders.

The manufacturing process is more labor-intensive and time-consuming. After the metal base is created, the recessed areas are filled with enamel, often requiring multiple applications for each color. The pin is then fired at high temperatures (800-900°C) to set the enamel. After cooling, the entire surface is polished down until smooth, creating a seamless transition between the metal and enamel components.

The result is a durable, high-quality pin with a glass-like finish that resists scratching and maintains its appearance over time. Hard enamel pins are often chosen for commemorative events, corporate gifts, and high-end collections where quality and longevity are paramount.

Die Struck Pins

Die-struck pins represent perhaps the most traditional and classic lapel pin style. These pins typically feature a single metal color (usually brass, copper, or nickel) with a design that’s stamped or struck into the metal itself.

The manufacturing process involves creating a die (a metal stamp) with the negative of the desired design. This die is then pressed into a softer metal like brass or copper with tremendous force, imprinting the design. The result is a pin with recessed and raised areas that create a three-dimensional effect through shadows and highlights rather than through color.

Die struck pins often receive additional treatments such as antiquing (darkening recessed areas to enhance contrast) or plating with gold, silver, or other finishes. Their monochromatic, classic appearance makes them particularly suitable for formal occasions, professional organizations, and awards.

Photo Etched/Offset Printed Pins

For designs requiring photographic detail or very fine lines, photo-etched or offset-printed pins offer solutions that other manufacturing methods cannot match. These pins begin with a flat metal base, typically made of brass or stainless steel.

In photo etching, the design is chemically etched into the metal using a photosensitive resist and acid bath. This allows for extremely fine detail, including thin lines and small text that would be impossible with die striking. The etched areas can then be filled with color by hand.

Offset printed pins take this a step further by using a printing process similar to that used in magazines. A full-color design is printed directly onto the metal surface and then covered with a protective epoxy dome to prevent scratching and fading. This method allows for photographic reproduction, gradients, and unlimited colors.

Specialty Pins

Beyond these main categories, numerous specialty pin types exist:

•3D or Die Cast Pins: Created using a mold rather than stamping, these pins can achieve more complex three-dimensional shapes.

•Glitter and Glow-in-the-Dark Pins: Incorporating special materials for unique visual effects.

•Spinner Pins: Featuring movable elements that can rotate or spin.

•Slider Pins: Including parts that can slide back and forth.

•Bobblehead Pins: With spring-mounted elements that bobble or shake.

•Pin-on-Pin: Designs where one pin is mounted on top of another for a layered effect.

Each of these specialty types offers unique possibilities for creative expression and functional design, expanding the lapel pin beyond its traditional boundaries.

Materials Used in Lapel Pin Manufacturing

The quality, appearance, and durability of a lapel pin are significantly influenced by the materials used in its construction. From the base metals that form the structure to the colorful enamels that bring designs to life, each component plays a crucial role in the final product. Understanding these materials can help you make informed decisions when purchasing or designing lapel pins.

Base Metals

The foundation of any lapel pin is its metal base, which provides structure and defines the pin’s overall shape and design elements. Several metals are commonly used in lapel pin manufacturing, each with distinct properties:

Iron

Iron is one of the most economical options for lapel pin bases. It’s relatively soft and easy to work with, making it suitable for simple designs and large production runs where cost is a primary concern. However, iron is susceptible to rusting if not properly finished and protected, which can limit its longevity, especially in humid environments.

Brass

Brass, an alloy of copper and zinc, is perhaps the most widely used metal for quality lapel pins. It offers an excellent balance of malleability (making it ideal for detailed designs), durability, and cost-effectiveness. Brass naturally has a warm, gold-like appearance, though it’s often plated with other metals for different finishes. Its resistance to corrosion makes it suitable for pins intended for long-term use.

Copper

Copper provides exceptional detail reproduction due to its softness and malleability. This makes it particularly valuable for intricate designs with fine lines and textures. Like brass, copper has natural antimicrobial properties and good corrosion resistance. Its distinctive reddish color can be preserved for a unique look or plated over for different aesthetic effects.

Zinc Alloy

Zinc alloys, particularly those used in die-casting processes, have become increasingly popular for lapel pin production. These alloys flow well when molten, allowing them to fill complex molds with excellent detail reproduction. Zinc alloy pins are typically lighter than their brass counterparts but still offer good durability. They’re particularly well-suited for three-dimensional designs that would be difficult to achieve with stamped methods.

Aluminum

For applications where weight is a concern, aluminum provides an ultra-lightweight alternative. While not as commonly used as other metals for traditional lapel pins, aluminum is sometimes employed for larger pins or badges where a heavier metal might be impractical. It’s also naturally corrosion-resistant, though it’s softer and more prone to bending than other options.

Stainless Steel

When maximum durability is required, stainless steel offers exceptional strength and corrosion resistance. However, its hardness makes it more difficult and expensive to work with, limiting its use primarily to high-end pins or those designed for harsh environments. Stainless steel pins typically have a sleek, modern appearance with excellent longevity.

Plating and Finishes

Once the base metal is formed into the desired shape, various plating processes can be applied to change its appearance and enhance durability:

Gold Plating

Gold electroplating applies a thin layer of gold over the base metal, creating a luxurious, warm appearance. Different karats and thicknesses of gold plating are available, affecting both price and durability. Gold plating is often used for commemorative pins, awards, and high-end corporate gifts.

Silver Plating

Silver plating provides a bright, reflective finish that complements many designs. Like gold, silver plating comes in various qualities and thicknesses. It’s worth noting that silver can tarnish over time if not properly maintained, though modern anti-tarnish coatings can mitigate this issue.

Nickel Plating

Nickel creates a bright, silver-like finish that’s more durable and tarnish-resistant than actual silver. It’s commonly used for pins where a clean, modern appearance is desired. Nickel plating also provides a good base for other finishes or can be the final finish itself.

Antiquing

Antiquing is a process that darkens recessed areas of a pin while leaving raised areas bright, enhancing contrast and giving the pin an aged, classic appearance. This finish is particularly effective on die-struck pins, where it helps highlight the dimensional aspects of the design.

Black Nickel/Black Metal

For a contemporary, sophisticated look, black nickel or other black metal finishes offer dramatic contrast, especially when combined with colorful enamel elements or when used to highlight specific design features.

Enamel and Color Materials

The vibrant colors that bring lapel pins to life come from various materials, depending on the manufacturing process:

Hard Enamel

True hard enamel is made from powdered glass that’s applied to recessed areas of the pin and then fired at high temperatures (800-900°C). This creates a smooth, glass-like surface that’s extremely durable and resistant to fading. The color selection for traditional hard enamel may be somewhat limited compared to other options, though modern techniques have expanded the available palette.

Soft Enamel

Soft enamel is typically an epoxy-based material that cures at much lower temperatures than hard enamel. It offers vibrant colors and can be applied in very precise patterns. While not as durable as hard enamel, soft enamel provides excellent color reproduction and is more cost-effective.

Epoxy Coatings

Clear epoxy is often applied as a protective dome over pins, particularly photo-printed pins, to protect the design from scratching and environmental damage. This creates a smooth, glossy finish that enhances colors and provides a professional appearance.

Specialty Materials

Modern pin manufacturing has incorporated numerous specialty materials for unique effects:

•Glitter enamel for sparkle and visual interest

•Glow-in-the-dark compounds for novelty pins

•Color-changing pigments that react to temperature or UV light

•Translucent enamels that create depth and visual effects

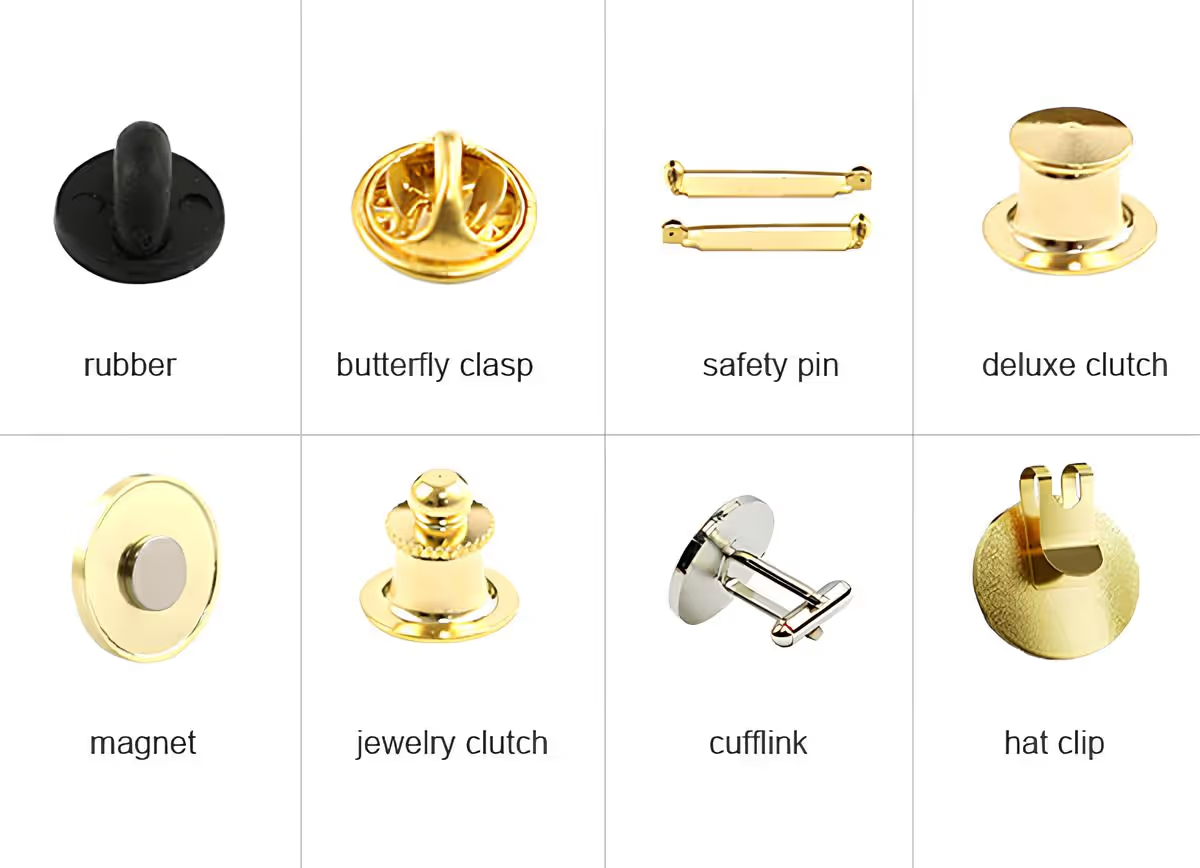

Backing Options

The backing of a lapel pin might seem like a minor consideration, but it significantly affects how the pin is worn and secured:

Butterfly Clutch

The most common backing, butterfly clutches (sometimes called military clatches), consist of a small metal or plastic piece that slides onto the pin post and holds securely with tension. They’re easy to use and provide a reliable attachment for most applications.

Rubber Clutch

Similar to butterfly clutches but made of rubber, these backings provide a secure grip while being gentle on fabrics. They’re particularly useful for delicate materials where metal clutches might cause damage.

Safety Pin Back

Reminiscent of traditional brooches, safety pin backs feature a hinged pin that closes securely. They’re easy to attach and remove, but may not be as secure as other options for heavy pins.

Magnetic Backing

Magnetic backings use two strong magnets—one attached to the pin and one placed on the opposite side of the fabric—to hold the pin in place without puncturing the material. These are ideal for delicate fabrics or situations where holes are undesirable, though they may not be as secure for heavy pins or active wear.

Screw and Nut

For maximum security, some pins use a threaded post with a small nut that screws into place. This is particularly useful for pins that will be worn on items subject to movement or for very valuable pins where loss would be concerning.

The choice of materials for a lapel pin involves balancing aesthetics, durability, and cost considerations. High-quality pins typically feature brass or copper bases with gold or nickel plating and either hard enamel or precisely applied soft enamel. However, innovations in materials and manufacturing continue to expand the possibilities, allowing for increasingly creative and unique pin designs to suit every purpose and preference.

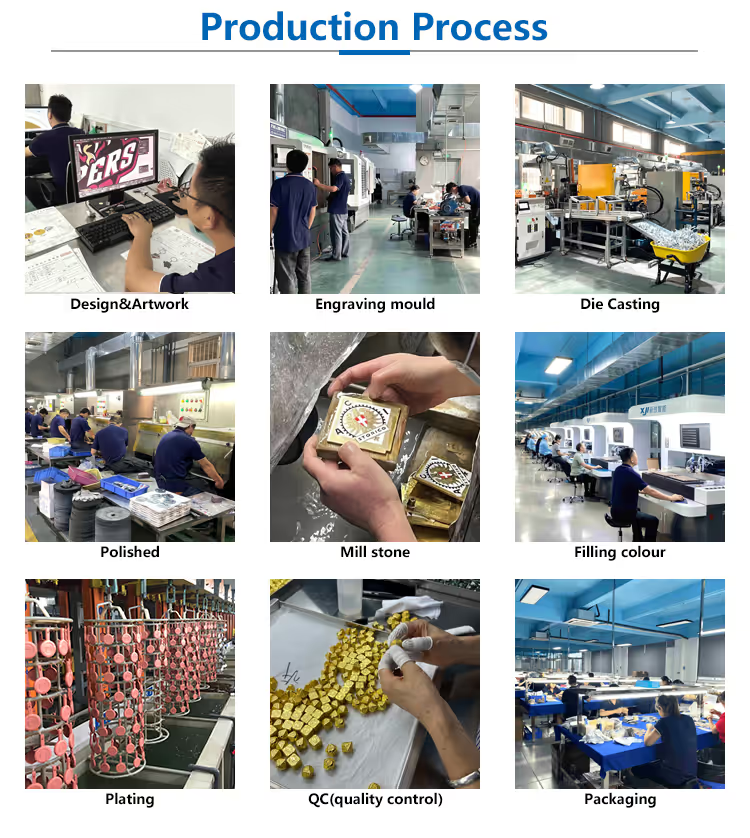

The Lapel Pin Manufacturing Process

The creation of a lapel pin is a fascinating journey from concept to finished product, involving multiple specialized steps and techniques. Whether you’re designing your custom pins or simply curious about how these miniature works of art come to life, understanding the manufacturing process provides valuable insight into the craftsmanship behind these popular accessories.

Design Phase

Every lapel pin begins as an idea, which must be translated into a manufacturable design:

Concept Development

The first step involves conceptualizing what the pin will represent and how it will look. This might be a logo, a commemorative design, an artistic expression, or any other visual concept. Considerations at this stage include the pin’s purpose, target audience, and where it will be worn.

Digital Design

Once the concept is established, it’s translated into a digital design using specialized software like Adobe Illustrator or CorelDRAW. Vector-based programs are preferred as they allow for precise scaling without loss of quality. During this phase, designers must consider manufacturing limitations:

•Minimum line thickness (typically 0.3-0.4mm)

•Minimum spacing between colors

•Color limitations based on the chosen manufacturing method

•Size and proportions of the overall pin

Design Approval

Before production begins, the design undergoes review and approval. Many manufacturers provide digital proofs or even physical samples for approval before proceeding with full production. This step is crucial for catching any issues that might affect the final product’s appearance or functionality.

Mold Creation

With the design finalized, the next step is creating the physical mold that will shape the pin:

Die Cutting

For traditional die-struck pins, a steel die is created by skilled craftspeople who cut the negative of the design into a steel block. This die will later be used to stamp the design into the softer metal of the pin. The precision of this die-cutting process directly affects the quality and detail of the finished pin.

CNC Milling

For more complex designs, computer numerical control (CNC) machines may be used to create precise molds based on the digital design. This automated process ensures accuracy and consistency, particularly for intricate details that would be challenging to cut by hand.

3D Modeling

For three-dimensional pins, the process may involve creating a 3D model that will be used to produce a mold for die-casting. This allows for pins with significant depth and dimensional detail that cannot be achieved through stamping alone.

Metal Formation

Once the mold is ready, the actual metal forming process begins:

Stamping (Die Struck Method)

For die-struck pins, sheets of the chosen base metal (typically brass, copper, or iron) are fed into stamping machines. The die is pressed into the metal with tremendous force—up to several tons of pressure—imprinting the design and cutting out the pin shape in a single operation. This creates the recessed areas that will later be filled with enamel or left as dimensional elements of the design.

Die Casting

For 3D pins or those with complex shapes, molten zinc alloy is injected into a mold cavity under high pressure. Once cooled and solidified, the metal takes the shape of the mold with exceptional detail reproduction. This method allows for more complex three-dimensional designs than stamping but typically requires larger production runs to be cost-effective.

Trimming and Filing

After the basic shape is formed, excess metal is trimmed away, and the edges are filed to remove any burrs or sharp points. This step ensures the pin has clean, smooth edges and prepares it for the next phases of production.

Plating and Finishing

With the basic metal form complete, various finishing processes are applied:

Polishing

The metal pin is polished to create a smooth surface and remove any imperfections from the stamping or casting process. This step is particularly important for areas that will remain exposed in the final design.

Plating

Electroplating applies a thin layer of finish metal (gold, silver, nickel, etc.) to the base metal. The pin is immersed in a solution containing dissolved metal ions, and an electric current causes these ions to bond to the pin’s surface. The duration of this process determines the thickness of the plating, which affects both appearance and durability.

Antiquing (Optional)

For pins with a vintage or classic look, an antiquing process may be applied. This involves applying a darkening agent to the entire pin and then polishing the raised areas, leaving the recessed areas darkened. This creates contrast and highlights the dimensional aspects of the design.

Coloring Process

The addition of color transforms the metal form into a vibrant finished product:

Hard Enamel (Cloisonné) Process

1.Enamel powder (ground glass) is carefully applied to the recessed areas of the pin

2.The pin is fired in a kiln at 800-900°C, melting the powder into a glass-like substance

3.Multiple applications and firings may be required to fill the recessed areas completely

4.After the final firing, the entire surface is ground down and polished until the enamel is level with the metal dividers

5.The result is a smooth, glass-like surface with vibrant colors

Soft Enamel Process

1.Colored epoxy or enamel paint is applied to the recessed areas of the pin

2.Each color is applied separately, requiring careful masking to prevent bleeding

3.The pin is baked at a relatively low temperature (compared to hard enamel) to cure the enamel

4.The metal dividers remain raised above the enamel, creating the characteristic textured feel

5.A clear protective coating may be applied to protect the colors

Photo/Offset Printing

1.A flat metal base is prepared with appropriate plating

2.The full-color design is printed directly onto the metal surface using a process similar to that used for magazines

3.A clear epoxy dome is applied over the printed image to protect it from scratching and fading

4.This method allows for photographic reproduction, gradients, and unlimited colors

Attachment and Backing

The final manufacturing step involves adding the mechanism that allows the pin to be attached to clothing or other items:

Post Attachment

A metal post or pin stem is soldered or welded to the back of the pin. The placement of this post is crucial—it must be positioned to ensure the pin hangs correctly when worn.

Quality Control

Before packaging, pins undergo inspection to ensure they meet quality standards. This includes checking for:

•Color accuracy and consistency

•Secure attachment of posts and clutches

•Surface finish quality

•Overall appearance and conformity to the approved design

Packaging

Finally, the completed pins are packaged according to specifications. This might involve individual poly bags, custom backing cards, presentation boxes, or bulk packaging, depending on the intended use and distribution method.

Modern Manufacturing Considerations

While the fundamental processes remain similar, modern lapel pin manufacturing has evolved with technological advances and changing market demands:

Global Production

The vast majority of lapel pins today are manufactured in China, particularly in and around Kunshan, a city near Shanghai. This region has developed specialized expertise and infrastructure for pin production, allowing for cost-effective manufacturing at scale.

Small Batch Production

Advances in manufacturing technology have made smaller production runs more feasible, enabling independent artists and small organizations to create custom pins in quantities as low as 50-100 units, whereas traditionally, minimum orders might have been in the thousands.

Sustainable Practices

Increasing awareness of environmental concerns has led some manufacturers to adopt more sustainable practices, including:

•Recycled metals for pin bases

•Water-based enamels with lower environmental impact

•Energy-efficient kilns and production facilities

•Plastic-free packaging options

Understanding the manufacturing process not only provides appreciation for the craftsmanship involved in creating lapel pins but also helps inform decisions when designing or purchasing pins. Each step in the process offers opportunities for customization and quality enhancement, resulting in the remarkable diversity of pins available today.

How to Wear a Lapel Pin Correctly

Wearing a lapel pin might seem straightforward, but there are nuances to proper placement, pairing, and occasion-appropriate styling that can elevate this small accessory from merely decorative to truly distinguished. Whether you’re new to lapel pins or looking to refine your approach, understanding these principles will help you wear your pins with confidence and style.

Traditional Placement

The classic and most universally accepted position for a lapel pin is on the left lapel of a jacket or coat. This placement has historical roots in military and formal dress traditions and remains the standard for most formal occasions.

On a Suit Jacket

When wearing a lapel pin with a suit jacket:

1.Place the pin on the left lapel, approximately at heart level

2.For jackets with a buttonhole on the lapel, the pin can either go through the buttonhole or be placed just above it

3.On jackets without a buttonhole, position the pin in the same relative location where a buttonhole would typically be

4.The pin should be perpendicular to the edge of the lapel or angled slightly upward

On Overcoats and Casual Jackets

The same general principles apply to overcoats and more casual jackets, though you may have more flexibility with placement:

1.The left lapel remains the standard position

2.For jackets with unusual lapel designs or no defined lapel, place the pin on the left chest area

3.Ensure the pin is secure, as heavier outerwear may put more stress on the attachment

Beyond the Lapel: Alternative Placements

While the lapel is traditional, contemporary fashion has embraced more creative pin placement:

Shirt Collar

Small lapel pins can be worn on a shirt collar for a subtle yet distinctive look. This works particularly well with:

•Button-down Oxford shirts

•Dress shirts without a tie

•Casual collared shirts

When placing a pin on a collar, position it on the left side, centered on the collar point or slightly toward the collar edge.

The breast pocket of a shirt, jacket, or even a dress can serve as an excellent location for a lapel pin:

1.Center the pin on the pocket

2.For pockets with flaps, place the pin on the flap rather than below it

3.Consider the weight of the pin—heavier pins may cause lighter fabrics to sag

Ties and Scarves

Lapel pins can double as tie pins or scarf accessories:

•On a tie, place the pin approximately halfway down the tie’s length

•For scarves, secure the pin where the scarf crosses or folds

•Ensure the backing is secure to prevent damage to delicate fabrics

Hats and Bags

For a contemporary twist:

•Place pins on the band of a fedora or other structured hat

•Add pins to canvas totes, backpacks, or the lapel of a leather bag

•Create a collection of pins on a denim jacket or vest for a personalized statement

Pairing Multiple Pins

Wearing multiple lapel pins has become increasingly popular, particularly in fashion-forward contexts:

Clustering

Creating a cluster of complementary pins can make a bold statement:

1.Choose pins with a unifying theme, color palette, or style

2.Arrange larger pins as focal points with smaller pins surrounding them

3.Maintain some negative space between pins to allow each design to be appreciated

Linear Arrangement

For a more structured approach:

1.Arrange pins in a vertical or horizontal line

2.Graduate sizes from largest to smallest

3.Consider the flow of the arrangement about the garment’s lines

Balance and Proportion

When wearing multiple pins:

•Consider the overall proportion relative to your frame—larger individuals can generally carry more or larger pins

•Balance the visual weight across the arrangement

•Ensure the combined weight doesn’t distort the fabric

Occasion-Appropriate Styling

Different contexts call for different approaches to lapel pin styling:

Formal Events

For black tie, white tie, or formal business events:

•Choose simple, elegant pins in precious metals

•Opt for subtle designs without bright colors

•Consider traditional symbols like a small floral pin or a discreet organizational emblem

•Limited to a single pin, perfectly positioned on the left lapel

Business Professional

In professional settings:

•Select pins that reflect organizational affiliation or professional achievements

•Choose designs that complement rather than distract from your overall appearance

•Consider the corporate culture—more conservative environments may call for more subtle pins

•Position pins precisely and ensure they’re securely fastened

Casual and Creative Settings

For casual wear or creative professional environments:

•Express personality through more colorful or unusual designs

•Experiment with multiple pins or unconventional placement

•Consider seasonal themes or current interests

•Use pins as conversation starters or expressions of personal values

Special Occasions

For weddings, commemorations, or celebrations:

•Choose pins that complement the event’s theme or color scheme

•Consider floral pins as alternatives to boutonnieres for weddings

•Wear pins that honor the occasion, such as memorial pins or celebration-specific designs

Common Mistakes to Avoid

Even this small accessory has its pitfalls:

Overcrowding

Wearing too many pins in a small area can create visual clutter and diminish the impact of each piece. When in doubt, edit your selection.

Insecure Attachment

Few things are more embarrassing than losing a cherished pin or having it hang awkwardly after becoming partially detached. Always check that the backings are secure before heading out.

Inappropriate Sizing

A pin that’s too large or too small for its placement can look disproportionate. Consider the scale of both the pin and the garment it adorns.

Conflicting Symbolism

Be aware of what your pins represent, particularly in professional or formal settings. Avoid unintentionally sending mixed messages through conflicting symbols.

Damaging Delicate Fabrics

Some pins, particularly those with heavier designs or sharp posts, can damage delicate fabrics. Consider using magnetic backings for valuable or fragile garments.

Seasonal and Trend Considerations

Like all accessories, lapel pin styles evolve with seasons and trends:

Seasonal Materials

•Spring/Summer: Lighter metals, floral designs, bright enamels

•Fall/Winter: Darker metals, textured finishes, jewel tones

Current Trends (2025)

•Minimalist, geometric designs in mixed metals

•Vintage and upcycled pins with historical significance

•Sustainable materials and production methods

•Interactive pins with moving parts or technological elements

•Personalized and customizable designs

Wearing a lapel pin is ultimately about personal expression within the framework of social context. By understanding the traditional rules, you gain the confidence to know when and how to break them creatively. Whether you opt for classic placement or innovative styling, the most important aspect is wearing your pin with intention and confidence.

Popular Uses and Occasions for Lapel Pins

Lapel pins serve a remarkable variety of purposes across different contexts, from formal professional settings to casual personal expression. Their versatility has contributed to their enduring popularity and continuous reinvention. Understanding the diverse uses and occasions for lapel pins can inspire new ways to incorporate these small but significant accessories into various aspects of life.

Corporate and Organizational Identity

One of the most established uses for lapel pins is as symbols of organizational affiliation and corporate identity:

Company Branding

Businesses frequently use lapel pins featuring their logos or corporate symbols to:

•Create visual unity among employees

•Enhance brand recognition at events and conferences

•Commemorate company milestones and anniversaries

•Distinguish between different departments or divisions within the organization

These corporate pins often become part of the unofficial uniform, particularly in customer-facing roles or at industry events where company representation is important.

Employee Recognition

Beyond basic branding, pins serve as powerful tools for employee recognition:

•Service anniversary pins acknowledging years of dedication

•Achievement pins celebrating sales targets or project completions

•Safety recognition pins in industries where safety milestones are significant

•Innovation or excellence awards represented through distinctive pin designs

These recognition pins not only honor the recipient but also create visible symbols of accomplishment that inspire others and reinforce organizational values.

Membership Identification

Organizations of all types use pins to identify members and create a sense of belonging:

•Professional associations and trade organizations

•Alumni groups and educational institutions

•Social clubs and recreational organizations

•Religious and spiritual communities

Membership pins often incorporate symbols meaningful to the group, creating instant recognition among fellow members and signaling affiliation to the broader public.

Political and Social Expression

Throughout history, lapel pins have played significant roles in political movements and social causes:

Campaign and Political Support

Political campaigns have long used pins as visible symbols of support:

•Candidate-specific designs during election seasons

•Party symbols and affiliations

•Issue-based pins advocating for specific policies or positions

In the United States, the American flag lapel pin became particularly significant in political contexts following the September 11, 2001, attacks, evolving into what some described as “the quickest sartorial method for a politician to telegraph patriotism.”

Awareness and Advocacy

Pins serve as powerful tools for raising awareness about social issues and causes:

•Colored ribbons representing various health conditions and awareness campaigns

•Symbols associated with social movements and human rights initiatives

•Environmental causes and sustainability advocacy

•Community support following disasters or tragedies

These awareness pins not only show personal support but often serve as conversation starters that help spread information about important causes.

Commemoration and Remembrance

Pins help preserve memory and honor significant events:

•Memorial pins for fallen service members or public figures

•Historical commemorations of significant dates and events

•Cultural heritage celebrations

•Personal remembrances of loved ones

Such commemorative pins connect wearers to collective or personal history, keeping important memories visible and present.

Special Events and Celebrations

The temporary nature of events makes pins perfect commemorative items:

Weddings and Celebrations

Personal celebrations often incorporate custom pins:

•Wedding party gifts with the date or the couple’s initials

•Anniversary celebrations

•Birth announcements and baby celebrations

•Graduation and achievement recognition

These pins serve as lasting mementos that can be kept long after the event itself has passed.

Conferences and Corporate Events

Professional gatherings frequently use pins for practical purposes:

•Attendee identification and access control

•Speaker or presenter designation

•VIP or special access indicators

•Event theme reinforcement and branding

Beyond their functional role, these pins often become souvenirs that remind participants of the experience and connections made.

Sports and Entertainment

Fans express their enthusiasm through pins related to their favorite activities:

•Team support and sports affiliations

•Tournament and championship commemorations

•Concert tours and music festivals

•Movie releases and entertainment franchises

The collectible nature of these pins often creates communities of enthusiasts who trade and display their collections.

Fashion and Personal Expression

In recent years, lapel pins have experienced a renaissance as fashion accessories and forms of personal expression:

Style Enhancement

Fashion-conscious individuals use pins to:

•Add color and interest to monochromatic outfits

•Create signature looks with consistently worn pins

•Customize and personalize mass-produced clothing

•Express seasonal themes or holiday spirit

The relatively low cost of pins compared to other accessories makes them an accessible way to refresh and personalize wardrobes.

Identity and Values Expression

Pins allow wearers to visually communicate aspects of their identity:

•Cultural and heritage pride

•Professional identities and accomplishments

•Hobbies and personal interests

•Values and beliefs

This form of self-expression through pins creates visual shorthand that can connect like-minded individuals and spark conversations.

Collecting and Trading

The collectible nature of pins has created communities centered around:

•Limited edition artist-designed pins

•Vintage and historical pins

•Theme-based collections (Disney, Hard Rock Cafe, Olympic pins)

•Pin trading events and conventions

What begins as casual collecting often evolves into serious hobby communities with their traditions, values, and social networks.

Educational and Institutional Uses

Educational settings have embraced pins for various purposes:

Academic Achievement

Schools and universities use pins to recognize:

•Honor society membership

•Academic excellence and achievement

•Graduation and completion milestones

•Special programs and educational tracks

These academic pins often carry significant prestige and become cherished symbols of educational accomplishment.

School Spirit and Identity

Educational institutions foster community through:

•School mascot and logo pins

•Athletic team support

•Club and activity participation

•Class year identification

These school-related pins help create community identity and often become nostalgic keepsakes of educational experiences.

Educational Tools

Some educational programs use pins as motivational tools:

•Reading achievement recognition

•Skill mastery acknowledgment

•Participation incentives

•Behavioral reinforcement

The visible nature of pins makes them effective motivators, particularly for younger students who can proudly display their accomplishments.

Tourism and Travel Mementos

Travelers have long collected pins as lightweight, durable souvenirs:

Destination Markers

Pins serve as visual records of places visited:

•City and country-specific designs

•Landmark representations

•National parks and natural wonders

•Cultural festivals and events

These travel pins often adorn bags, hats, or dedicated display items, creating visual maps of personal journeys.

Transportation and Hospitality

The travel industry itself uses pins for:

•Airline and cruise line status recognition

•Hotel and resort branding

•Tour group identification

•Transportation anniversaries and commemorations

Frequent travelers often accumulate these industry pins as badges of their experiences and status.

The remarkable diversity of lapel pin uses demonstrates their cultural significance beyond mere decoration. These small accessories carry meanings ranging from solemn commemoration to playful self-expression, professional achievement to personal passion. Their ability to communicate so much in such a small format ensures their continued relevance across contexts and generations.

Custom Lapel Pin Design: Creating Your Own Pin

The process of creating custom lapel pins transforms a simple accessory into a personal or organizational statement. Whether you’re designing pins for a corporate event, a special celebration, or as artistic merchandise, understanding the design and production process will help you create pins that effectively communicate your intended message and meet your quality expectations.

Before diving into the technical aspects of pin design, it’s important to clarify your vision and purpose:

Purpose and Audience

The first step in designing an effective custom pin is understanding its purpose and intended audience:

•Who will wear the pin? Consider the demographics, style preferences, and values of your target wearers.

•What is the pin’s primary function? Recognition, commemoration, promotion, fashion, or something else?

•Where will the pin typically be worn? Formal business attire requires different design considerations than casual wear or bags.

•How long is the pin intended to be used? Event-specific pins might prioritize visual impact over durability, while long-term recognition pins should emphasize quality and longevity.

Answering these questions will guide your decisions throughout the design process.

Visual Elements

Effective pin designs balance aesthetic appeal with practical considerations:

Logo and Imagery

If incorporating existing logos or imagery:

•Ensure you have proper rights to use all visual elements

•Consider how complex logos might need to be simplified for the pin format

•Maintain recognizable elements while adapting to the constraints of pin manufacturing

Color Selection

Color choices significantly impact both aesthetics and manufacturing:

•Limit colors to 4-8 for most pin types to control costs and complexity

•Ensure sufficient contrast between adjacent colors

•Consider how colors will translate in different pin manufacturing processes

•Remember that metallic elements (gold, silver, copper) count as colors in your palette

Text and Typography

If including text:

•Keep wording minimal and impactful

•Choose fonts that remain legible at small sizes

•Ensure adequate spacing between letters

•Consider how thin font elements might translate in the manufacturing process

Size and Shape

The physical dimensions of your pin affect both visibility and wearability:

•Standard sizes range from 0.75″ to 2″ in the longest dimension

•Unusual shapes can create visual interest, but may increase production costs

•Consider the weight of larger pins and how they’ll hang on different fabrics

•Remember that extremely small details may be lost in production

Technical Design Requirements

Beyond aesthetic considerations, technical requirements ensure your design can be successfully manufactured:

File Preparation

Professional pin production requires properly formatted design files:

•Vector Format: Adobe Illustrator (.ai) or CorelDRAW (.cdr) files are preferred for most pin manufacturing

•Resolution: For photo or printed pins, high-resolution (at least 300 dpi) images are essential

•Color Mode: Specify colors in PMS (Pantone Matching System) for the most accurate color reproduction

•Outlines: Convert all text to outlines/curves to prevent font substitution issues

•Layers: Organize design elements in logical layers for easier manufacturing interpretation

Design Limitations

Different manufacturing methods have specific limitations to consider:

Die Struck Pins

•Minimum metal line width: 0.3mm

•No color gradients are possible

•Limited to metal finishes with optional antiquing

Soft Enamel Pins

•Minimum metal line width between colors: 0.3mm

•Each color must be contained within metal borders

•Gradients are not possible within a single color area

Hard Enamel Pins

•Similar limitations to soft enamel

•Colors must be separated by metal dividers

•More limited color palette than soft enamel

Printed Pins

•Can accommodate gradients, photographs, and unlimited colors

•May not have the same perceived value as metal-based pins

•Require a protective coating to prevent scratching

Design for Manufacturing

Working within manufacturing constraints ensures the best results:

•Avoid extremely fine details that may be lost in production

•Ensure adequate space between color areas

•Consider how raised and recessed areas will affect the final appearance

•Provide clear instructions about metal finishes and color specifications

Choosing the Right Type of Pin

Selecting the appropriate manufacturing method is crucial for achieving your desired results:

Soft Enamel

Best for:

•Designs with multiple colors

•Budget-conscious projects

•Pins where a textured feel is desirable

•Vibrant, eye-catching designs

Considerations:

•Recessed enamel creates a textured surface

•Colors appear vibrant due to light reflection

•More affordable than hard enamel

•Available in a wide range of colors

Hard Enamel (Cloisonné)

Best for:

•Premium, high-quality presentations

•Long-lasting commemorative pins

•Professional and formal contexts

•Designs where a smooth finish is important

Considerations:

•Smooth, polished surface

•More durable than soft enamel

•Higher cost than other options

•Slightly more limited color palette

Die Struck

Best for:

•Classic, traditional appearances

•Formal recognition and awards

•Designs emphasizing metal detail

•Corporate and organizational pins

Considerations:

•No enamel colors, only metal finishes

•Dimensional appearance through raised and recessed areas

•Can include antiquing for contrast

•Classic, substantial feel

Offset Printed

Best for:

•Photographic reproduction

•Designs with gradients or fine details

•Full-color artwork

•Quick production timelines

Considerations:

•Allows unlimited colors and gradients

•Requires an epoxy dome for protection

•Less dimensional than other pin types

•Often more affordable for complex designs

Specialty Options

For unique projects, consider specialty manufacturing techniques:

•3D/Die Cast Pins: For dimensional designs with significant depth

•Spinner Pins: Incorporating moving elements

•Glow-in-the-Dark: Using special luminescent materials

•Glitter Enamel: Adding sparkle and visual interest

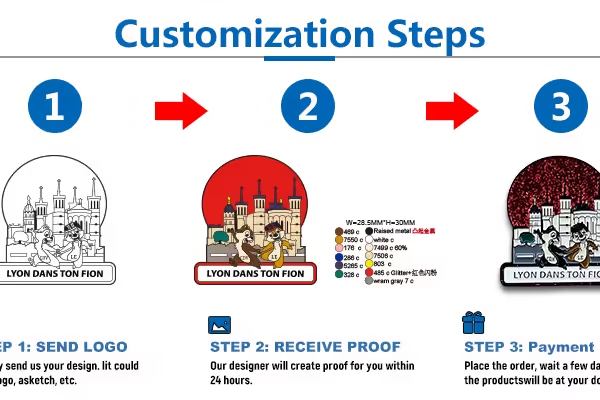

The Custom Pin Production Process

Understanding the production timeline and process helps set realistic expectations:

Design Submission and Review

After submitting your design:

1.The manufacturer reviews for technical feasibility

2.Adjustments may be suggested to improve manufacturability

3.A production proof is created for approval

Proof Approval

Before production begins:

1.Review digital proofs carefully for accuracy

2.Check colors, text, and all design elements

3.Request physical proofs for critical projects (additional time/cost)

4.Provide written approval to proceed

Production Timeline

Typical production timelines after approval:

•Standard production: 2-4 weeks

•Rush orders: 7-14 days (additional fees usually apply)

•Shipping: 3-5 days domestic, 7-14 days international

Quality Control

Professional manufacturers implement quality checks:

1.Initial sample inspection

2.Mid-production checks

3.Final inspection before packaging

4.Random sampling for detailed examination

Cost Considerations

Several factors affect the cost of custom pin production:

Quantity

Production volume significantly impacts per-unit cost:

•Minimum orders typically start at 50-100 pins

•Per-unit costs decrease substantially at higher quantities

•Consider future needs when determining order size

Size and Complexity

Physical characteristics affect pricing:

•Larger pins require more materials and cost more

•Complex shapes may require additional processing

•The number of colors impacts production complexity and cost

•Special finishes and effects add to the base price

Quality and Materials

Material choices influence both cost and quality:

•Base metal selection (brass vs. iron vs. zinc alloy)

•Plating options (gold, silver, nickel, black nickel)

•Enamel type and quality

•Backing options and packaging

Additional Services

Consider whether you need:

•Custom packaging or backing cards

•Individual poly bagging

•Special shipping arrangements

•Rush production

Working with Manufacturers

Selecting the right manufacturing partner ensures a smooth process:

Evaluating Manufacturers

When choosing a pin manufacturer, consider:

•Portfolio quality and relevance to your project

•Years in business and reputation

•Communication, responsiveness,s and clarity

•Pricing transparency

•Production capabilities and limitations

•Minimum order requirements

•Quality guarantees and policies

Communication Best Practices

Clear communication prevents costly misunderstandings:

•Provide detailed written specifications

•Reference existing pins or examples when possible

•Ask questions about anything unclear

•Get all agreements in writing

•Establish clear timelines and expectations

Intellectual Property Considerations

Protect your designs and respect others’ rights:

•Ensure you have the rights to all elements in your design

•Consider whether to trademark distinctive pin designs

•Discuss confidentiality with your manufacturer

•Be cautious about reproducing licensed characters or logos without permission

Creating custom lapel pins allows for personal expression, organizational branding, or commemorating special events in a tangible, wearable format. By understanding the design considerations, manufacturing processes, and production requirements, you can create pins that effectively communicate your message while meeting your quality and budget requirements. Whether for professional recognition, personal expression, or promotional purposes, custom pins offer a unique combination of practicality and symbolism that few other items can match.

Lapel Pin Care and Maintenance

Proper care and maintenance of lapel pins not only preserves their appearance but also extends their lifespan, protecting both their aesthetic value and any sentimental or historical significance they may hold. Whether you’re a casual wearer or a serious collector, these guidelines will help keep your pins looking their best for years to come.

Everyday Handling

The way you handle your pins during regular use significantly impacts their longevity:

Proper Attachment and Removal

To prevent damage when attaching or removing pins:

1.Clean hands: Always handle pins with clean, dry hands to avoid transferring oils and dirt

2.Gentle pressure: Apply even, gentle pressure when pushing pins through fabric

3.Support fabric: Hold fabric taut but not stretched when inserting pins

4.Careful removal: Remove pins by grasping the pin body, not decorative elements

5.Two-handed technique: Use one hand to stabilize the pin while the other removes the backing

Avoiding Common Damage

Prevent common sources of pin damage:

•Avoid impact: Don’t let pins knock against hard surfaces

•Prevent scratching: Keep pins separated from keys, jewelry, and other hard objects

•Mind the backing: Ensure clutches or backings are fully secured to prevent loss

•Fabric considerations: Be cautious when pinning to delicate fabrics that may tear or show pin holes

•Weather awareness: Protect pins from extended exposure to direct sunlight, extreme temperatures, or high humidity

Cleaning Techniques

Regular cleaning maintains appearance and prevents long-term damage:

Basic Cleaning

For routine maintenance:

1.Dust removal: Use a soft, dry microfiber cloth to gently wipe away dust and surface dirt

2.Light polishing: Lightly buff metal areas with a jewelry polishing cloth

3.Compressed air: Use canned air to clean small crevices and detailed areas

4.Frequency: Clean displayed pins every few weeks; store pins before and after storage

Deep Cleaning Methods

For more thorough cleaning when necessary:

Metal Pins (No Enamel)

1.Prepare a solution of mild dish soap and warm (not hot) water

2.Dip a soft toothbrush in the solution and gently scrub the pin

3.Rinse thoroughly with clean water

4.Dry immediately and completely with a soft cloth

5.Allow to air dry fully before storing

Enamel Pins

1.Dampen a soft cloth with warm water

2.Add a tiny amount of mild soap if necessary

3.Gently wipe the pin’s surface, avoiding excessive pressure

4.Use a cotton swab for cleaning between metal dividers

5.Wipe with a clean, damp cloth to remove soap residue

6.Dry thoroughly with a soft cloth

Specialty Pins

•Glitter pins: Avoid wet cleaning; use only dry methods

•Vintage pins: Test cleaning methods on a small, inconspicuous area first

•Pins with gemstones or delicate elements: Consider professional cleaning

What to Avoid

Certain cleaning practices can damage pins:

•Harsh chemicals: Never use bleach, ammonia, or abrasive cleaners

•Soaking: Don’t submerge pins, especially those with adhesives or multiple components

•Ultrasonic cleaners: These can loosen stones or damage enamel

•Abrasive materials: Avoid paper towels, rough cloths, or brushes with stiff bristles

•Steam cleaning: Heat and moisture can damage enamel and adhesives

Storage Solutions

Proper storage prevents damage when pins aren’t being worn:

Short-Term Storage

For pins in regular rotation:

•Pin cushions: Traditional pin cushions work well for temporary storage

•Magnetic boards: Magnetic surfaces allow for display and easy access

•Cork boards: Push pins directly into the cork for visible storage

•Fabric strips: Dedicated fabric strips mounted on walls or inside cabinet doors

Long-Term Storage

For preservation and organization:

•Pin albums: Similar to photo albums, but with foam pages that pins can be inserted into

•Compartmentalized boxes: Boxes with divided sections prevent pins from touching

•Archival envelopes: Individual acid-free paper or glassine envelopes protect valuable pins

•Display cases: Glass-fronted cases protect while allowing visibility

•Pin binders: Specialized binders with pin-holding pages for collectors

Storage Conditions

Environmental factors affect pin preservation:

•Temperature: Store in moderate, stable temperatures (65-75°F/18-24°C)

•Humidity: Maintain moderate humidity (40-50%) to prevent metal corrosion

•Light exposure: Avoid direct sunlight, which can fade enamel colors

•Air circulation: Some airflow prevents moisture buildup

•Contaminants: Keep away from chemicals, perfumes, and household cleaners

Preventing and Addressing Common Issues

Even with proper care, pins may develop problems that require attention:

Tarnish and Oxidation

Metal components naturally tarnish over time:

•Prevention: Store with anti-tarnish strips or in tarnish-resistant containers

•Treatment: Gently polish with a jewelry cloth designed for the specific metal

•Severe tarnish: Commercial tarnish removers can be used carefully on metal-only areas

•Patina: Consider whether an aged appearance is desirable before removing

Loose or Broken Parts

Mechanical issues require prompt attention:

•Loose posts: Have a jeweler or pin specialist resolder posts

•Damaged clutches: Replace with new clutches of the appropriate size

•Separated elements: Use appropriate adhesive (epoxy for metal, clear craft glue for lightweight components)

•Chipped enamel: Professional repair is recommended for valuable pins

Color Fading

Enamel and printed colors can fade over time:

•Prevention: Minimize exposure to direct sunlight and UV light

•Display options: Use UV-filtering glass or acrylic for display cases

•Rotation: Periodically rotate displayed pins to distribute light exposure

•Documentation: Photograph pins when new to document original appearance

Display Techniques

Proper display allows enjoyment while protecting pins:

Home Display Options

For personal collections:

•Shadow boxes: Framed, recessed displays with pin-friendly backing

•Display boards: Cork, foam, or fabric-covered boards

•Specialized displays: Commercial pin display stands and frames

•Rotation systems: Periodically change displayed pins to reduce wear and exposure

Wearing Considerations

When pins are worn:

•Backing security: Double-check that backings are secure before wearing

•Placement planning: Consider the activity level when deciding where to place pins

•Clothing material: Thicker fabrics provide better support for heavier pins

•Activity awareness: Remove pins before engaging in vigorous physical activity

•Weather protection: Consider whether pins will be exposed to rain or snow

Special Considerations for Collectors

Serious collectors should implement additional practices:

Documentation

Maintain records of your collection:

•Inventory system: Catalog pins with descriptions, acquisition dates, and values

•Photography: Take clear photos of each pin for insurance and reference

•Provenance: Record the history and origin of significant pins

•Valuation: Have valuable pins professionally appraised

Insurance

Protect valuable collections:

•Homeowner’s/renter’s insurance: Check whether your policy covers collectibles

•Specialized insurance: Consider dedicated collectibles insurance for valuable collections

•Documentation requirements: Understand what documentation insurers require

•Storage requirements: Some insurance policies specify required storage conditions

Authentication and Preservation

For rare or valuable pins:

•Professional authentication: Have significant pieces authenticated by experts

•Conservation consultation: Seek professional advice for historical or valuable pins

•Handling tools: Use cotton gloves and specialized tools when handling valuable pins

•Environmental monitoring: Consider using humidity and temperature monitors in storage areas

Restoration and Repair

When damage occurs despite preventive measures:

DIY Repairs

Simple issues you may address yourself:

•Replacing backings: Standard butterfly clutches and pin backs are easily replaced

•Minor cleaning: Basic tarnish and dirt can often be addressed with gentle cleaning

•Straightening bent posts: Carefully straighten using needle-nose pliers with a protective coating

Professional Restoration

When to seek professional help:

•Valuable or sentimental pins: Don’t risk DIY repairs on important pieces

•Enamel damage: Chipped or cracked enamel requires specialized repair

•Structural issues: Broken or severely bent metal components

•Antique pins: Historical pieces deserve professional conservation

•Finding specialists: Jewelers, metal artists, or dedicated pin restorers

Proper care and maintenance of lapel pins is relatively simple but requires consistency and attention to detail. By implementing these practices, you can ensure that your pins—whether family heirlooms, professional achievements, or personal collections—remain in excellent condition for years or even generations to come. The small effort required for proper pin care is minimal compared to the value of preserving these miniature works of art and the memories or significance they represent.

Lapel Pin Market Trends in 2025

The lapel pin market continues to evolve in response to changing fashion sensibilities, technological innovations, and broader cultural shifts. In 2025, several distinct trends have emerged, shaping both how pins are designed and manufactured and how they’re being used by individuals and organizations. Understanding these trends provides valuable insight for collectors, designers, and businesses looking to leverage the enduring appeal of these small but significant accessories.

Design Trends

The aesthetic direction of lapel pins reflects broader movements in design, art, and fashion:

Minimalist Revival

In contrast to the detailed, colorful designs that dominated recent years, 2025 has seen a significant shift toward minimalist aesthetics:

•Clean lines and simple shapes that create a bold visual impact

•Limited color palettes, often monochromatic or with just one accent color

•Negative space is used as an active design element

•Abstract representations rather than literal imagery

•Geometric patterns that create modern, sophisticated appearances

This minimalist approach aligns with broader fashion trends toward understated elegance and timeless design principles.

Mixed Materials

Innovative combinations of materials are pushing the boundaries of traditional pin manufacturing:

•Metal and wood combinations create a textural contrast

•Ceramic elements incorporated into metal frameworks

•Textile inclusions adding unexpected softness to hard surfaces

•Recycled materials repurposed into decorative elements

•Silicone and rubber components for flexible, three-dimensional effects

These material explorations are expanding the definition of what constitutes a lapel pin while creating distinctive tactile experiences.

Nostalgic and Vintage-Inspired

Drawing on historical design languages continues to be a strong trend:

•Mid-century modern aesthetics with characteristic shapes and color palettes

•Art deco revival featuring geometric patterns and symmetry

•Vintage advertising imagery and typography

•Historical emblems and symbols reinterpreted for contemporary contexts

•Retro-futurism blends past visions of the future with modern sensibilities

This nostalgic turn reflects broader cultural interest in authenticity and historical connection in an increasingly digital world.

Interactive and Functional Designs

Pins that do more than simply adorn are gaining popularity:

•Spinner elements that rotate or move

•Magnetic components that can be reconfigured

•Glow-in-the-dark features for nighttime visibility

•Scented elements add an unexpected sensory dimension

•Pins with practical functions, such as bottle openers or small tools

These interactive designs transform pins from passive decorations to engaging accessories that invite interaction.

Manufacturing and Technology Trends

Advancements in production techniques and materials are expanding creative possibilities:

Sustainable Production

Environmental consciousness is significantly influencing the pin manufacturing:

•Recycled metals reduce the environmental impact of production

•Water-based enamels with lower toxicity than traditional options

•Energy-efficient kilns and equipment reduce carbon footprints

•Biodegradable packaging replacing plastic alternatives

•Upcycled components incorporating pre-existing materials

Manufacturers are increasingly promoting their sustainable practices as selling points, responding to consumer demand for environmentally responsible products.

Digital Integration

The merging of physical pins with digital experiences is creating new possibilities:

•NFC-enabled pins that link to websites or digital content when scanned

•AR (Augmented Reality) features that animate or expand pin designs when viewed through smartphone apps

•QR codes are subtly incorporated into designs for additional information or experiences

•Digital authentication for limited edition or collectible pins

•Social media integration facilitates sharing and community building

These technological enhancements extend the PIN experience beyond the physical object, creating multi-dimensional engagement opportunities.

Advanced Manufacturing Techniques

New production methods are enabling previously impossible designs:

•3D printing for prototyping and small-batch production

•Laser cutting for unprecedented precision in metal work

•Multi-level molding creates complex three-dimensional forms

•Micro-engraving allows for extremely fine detail

•Advanced plating techniques produce unique finishes and effects

These technological advancements are particularly significant for independent designers and small manufacturers, democratizing production capabilities once limited to large factories.

Customization and On-Demand Production

The ability to produce smaller quantities economically is transforming the market:

•Print-on-demand services are making custom pins accessible to individuals

•Virtual design tools allowing non-designers to create personalized pins

•Rapid prototyping enables iterative design processes

•Drop shipping models connect designers directly with customers

•Localized production reduces shipping times and environmental impact

This trend toward customization reflects broader consumer expectations for personalized products and experiences.

Market and Consumer Trends

How pins are being used, collected, and marketed continues to evolve:

Micro-Collections and Limited Releases

The collectible pin market has shifted toward curated, limited offerings:

•Artist collaboration series featuring well-known designers

•Extremely limited editions (often under 100 pieces) create scarcity

•Numbered and signed pins are treated as miniature art pieces

•Themed micro-collections of 3-5 pins released as sets

•Subscription models delivering exclusive pins to members

This approach builds on collector psychology while creating sustainable business models for independent creators.

Corporate Rebranding Through Pins

Businesses are rediscovering pins as versatile branding tools:

•Employee engagement programs using pins as recognition and team-building tools

•Customer loyalty pins reward repeat business

•Brand ambassador programs where pins identify official representatives

•Event-specific pins create memorable touchpoints

•Values and initiative pins communicate corporate priorities and culture

This corporate revival represents a return to traditional uses of pins while incorporating contemporary design sensibilities and strategic objectives.

Community and Identity Expression

Pins continue to serve as powerful symbols of affiliation and identity:

•Pronoun pins indicating preferred gender pronouns

•Cause-related designs supporting social and political movements

•Neurodiversity and disability awareness pins

•Cultural heritage celebration through traditional symbols and imagery

•Professional identity pins for emerging fields and disciplines

These identity-focused pins reflect the increasing importance of visual signifiers in communicating personal values and affiliations.

Digital Marketplace Evolution

How pins are bought and sold continues to transform:

•Dedicated pin marketplaces specializing exclusively in pin trading and sales

•Authentication services verifying rare or valuable pins

•Virtual pin shows connecting collectors globally

•Blockchain verification for limited editions and artist proofs

•Secondary market platforms facilitating collector-to-collector sales

These specialized marketplaces are creating more robust ecosystems for collectors while providing new revenue streams for designers and manufacturers.

Regional and Global Trends

Geographic variations in pin popularity and usage create diverse market opportunities:

Asia-Pacific Growth

The Asia-Pacific region is experiencing particularly strong growth in pin culture:

•Character and mascot pins building on kawaii aesthetic traditions

•Corporate gifting, incorporating pins into business relationship building

•Heritage celebration through traditional art forms adapted to pin formats

•Luxury positioning with high-end materials and craftsmanship

•Pop culture collaboration between Eastern and Western design influences

This regional growth is creating new markets for designers and manufacturers while introducing distinctive aesthetic approaches.

European Craftsmanship Focus

European markets are emphasizing artisanal quality and heritage:

•Traditional enamel techniques preserved and celebrated

•Historical reproduction pins connecting to regional heritage

•Artisanal and handcrafted approaches over mass production

•Museum collaborations creating pins based on cultural collections

•Fashion house limited editions positioning pins as luxury accessories

This focus on craftsmanship and heritage creates premium market segments while preserving traditional manufacturing knowledge.

North American Indie Scene

Independent designers continue to drive innovation in North American markets:

•Pop culture commentary through clever, referential designs

•Political and social statement pins addressing current issues

•Convention and festival exclusives create event-specific collectibles

•Craft brewery and local business collaboration supporting local economies

•Outdoor and adventure themes connecting to regional activities and landscapes

This vibrant independent scene maintains pins as relevant cultural artifacts while providing entry points for new designers and collectors.

Future Outlook

Looking beyond current trends, several developments appear poised to shape the future of lapel pins:

Technological Integration

The boundary between physical pins and digital experiences will likely continue to blur:

•Smart materials that change appearance based on environmental conditions

•Miniaturized electronics incorporated into pin designs

•Digital collectibles paired with physical pins as authentication

•Customization algorithms generate unique designs based on user data

•Virtual pin collections existing alongside physical ones

These technological developments may fundamentally transform what constitutes a “pin” while maintaining the core function of personal expression and affiliation.

Sustainability Imperative

Environmental considerations will increasingly influence all aspects of the pin market:

•Circular economy models for recycling and repurposing pins

•Carbon-neutral manufacturing is becoming an industry standard

•Biodegradable components for temporary or event-specific pins

•Rental and sharing models for high-end or special occasion pins

•Transparent supply chains allow consumers to make informed choices

This sustainability focus reflects both consumer demand and regulatory pressures affecting all manufacturing sectors.

Market Consolidation and Specialization

The business landscape for pin production and sales is likely to evolve:

•Specialized manufacturers focusing on particular techniques or markets

•Designer-manufacturer partnerships create vertical integration

•Platform consolidation as digital marketplaces mature

•Authentication and appraisal services are becoming more formalized

•Investment potential for rare or significant pins is gaining recognition

These business evolutions may create more stable and sophisticated market structures while potentially raising barriers to entry for new participants.

The lapel pin market in 2025 demonstrates remarkable resilience and adaptability, continuing to find relevance in an increasingly digital world. By combining traditional craftsmanship with technological innovation and responding to contemporary social and environmental concerns, pins maintain their unique position as small but significant vehicles for personal expression, organizational identity, and cultural commentary. For collectors, designers, and businesses alike, understanding these evolving trends provides valuable insight into how these miniature accessories continue to make a maximum impact.

FAQ About Lapel Pins

The terms “lapel pin” and “enamel pin” are often used interchangeably, but there are subtle distinctions. A lapel pin refers to any small pin designed to be worn on the lapel of a jacket or other clothing items. It’s a broader category that includes various manufacturing techniques and materials.

An enamel pin specifically refers to pins made using enamel coloring in recessed areas between metal dividers. Enamel pins are a subset of lapel pins, distinguished by their manufacturing process involving colored enamel fill. While all enamel pins are lapel pins, not all lapel pins are enamel pins—some may be die-struck metal without enamel, photo-printed, or made using other techniques.

In contemporary usage, “enamel pin” has become somewhat of a catchall term for collectible, decorative pins, even when they technically use different manufacturing methods. This linguistic evolution reflects the recent popularity of collectible pins in fashion and pop culture.

Attaching lapel pins while minimizing damage to your clothing requires careful technique and sometimes alternative attachment methods:

Standard Pin Attachment:

1.Select a sturdy area of the garment that can support the pin’s weight

2.Push the pin through from the front, being careful not to catch or snag threads